Asset Monitoring System for LAND Instruments

LAND Instruments International are the acknowledged world leader in the design and application of infrared temperature measurement for industry. They have a reputation as both an innovator and manufacturer of high-quality precision radiation thermometers and thermometer systems.

The infrared temperature measurement product range includes:

- Fixed, on-line thermometers and systems - for process control and product quality

- Portable infrared thermometers - for spot measurements

- Process thermal imagers - for asset management and process control

- High Resolution, infrared scanners for fast-moving materials

- Calibration Furnaces

The requirement

LAND Instruments required an asset monitoring system that would check and record images from a total of 44 thermal imaging cameras operating on a 24/7 basis. The cameras were located in a factory warehouse where they monitored large stacks of petroleum coke; this is a by-product of crude oil with high value because of its market demand in the steel industry.

The thermal images from the cameras needed to be sent to a PC that would monitor the temperature, analyse the data and alert the engineers in case of any abnormality. The final analysis of the data could then be carried out by specialist software installed on the PC.

The system also had to be able to record data over several months so that temperature patterns could be established and analysed. It was crucial that the solution had no single point of failure and incorporated redundancy, as the information stored was critical to the customer and could not be lost.

The big challenge faced by the Amplicon engineering team was to specify an integrated system that would meet all of the customer requirements but also deliver against the environmental hurdles of temperature, redundancy and safety. In addition, the project had a very tight delivery schedule.

The solution

Once the requirement was fully understood, the Amplicon Engineering Team worked with LAND Instruments to specify a solution that would integrate the required hardware and provide the functionality and operational performance needed by the customer.

The first thing that had to be considered was how the thermal imaging cameras would connect to the PCs in the most cost-effective way, taking into account the distance, temperature and redundancy requirement.

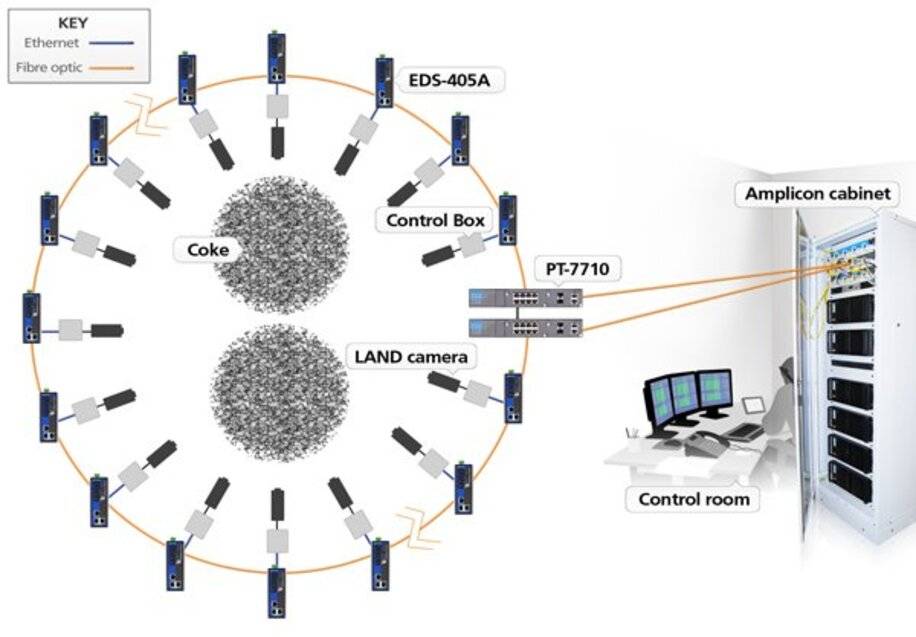

To ensure reliable network connectivity, the Amplicon Engineering Team specified the Moxa EDS-405A-SS-SC-T managed Ethernet switch. Each camera was connected to an EDS-405A-SS-SC-T via a control box using Ethernet technology. The EDS-405A-SS-SC-T was designed into the system in order to transmit the data with single-mode fibre optic cabling.

All EDS-405A switches were connected in a ring topology with each camera transmitting data back to the control room where the PC was located. The Moxa EDS-405A-SS-SC-T is an entry-level five port managed Ethernet switch specially designed for industrial applications. Key features of the EDS-405A-SS-SC-T switch include Turbo Ring, Turbo Chain and RSTP/STP for network redundancy, as well as offering an extended temperature range of -40 to 75°C.

In a ring topology, all the nodes are connected to each other in such a way that they make a closed loop. In this case, each switch was designed to communicate with two adjacent switches to offer backup network path redundancy.

A modular rackmount Ethernet switch system - the Moxa PT-7710 together with the PM-7200-2SSC and PM-7200-8TX modules - were installed in the control rack cabinet. This was designed to receive all the data transmitted from the EDS-405A switches via fibre optics and transfer it to the PC.

The PT-7710 Ethernet switch is IEC 61850-3, IEEE 1613 and EN50155/EN50121-4 compliant, they offer Turbo Ring, Turbo Chain, RSTP/STP for network redundancy and have an extended temperature range of -40 to 85°C. Once the network hardware was specified, it was important to evaluate what Amplicon PC would best meet the customer requirements. Each of the PCs needed to be extremely reliable, robust and offer double redundancy to ensure the system would provide

Based on the stringent PC hardware requirements the Amplicon Engineering Services Team specified two Impact 4000 Xeon storage servers with RAID hard drives. With this configuration, the data could be transmitted to both PCs that had mirrored hard drives offering dual redundancy.

In order to store the data for a long period of time, additional Impact 4000 Xeon storage servers were integrated into the rack cabinet with larger hard drives. The Amplicon Impact 4000 industrial computers are manufactured by Amplicon incorporating industrial motherboards to achieve hardware life cycles of up to 5-7 years.

Finally, the information processed by each PC/server needed to be displayed on a single screen. For this, the Amplicon 1U rackmount KwikDraw-A 171-8 was specified. The unit offered a 17" TFT LCD monitor, 8 port KVM and keyboard/touchpad. The Amplicon KwikDraw-A series is undoubtedly one of the highest quality industrial, rack-mount KVM solutions available, using specially selected industrial components.

Results

The idea of outsourcing the build of a complete system was

With this being the first step into out sourcing our cabinet builds, my experience of the Amplicon engineering team and their willingness to make corrections to the design during the first build has given me the confidence to choose Amplicon again.

Mike Glover, Project Manager - Engineered Solutions - LAND